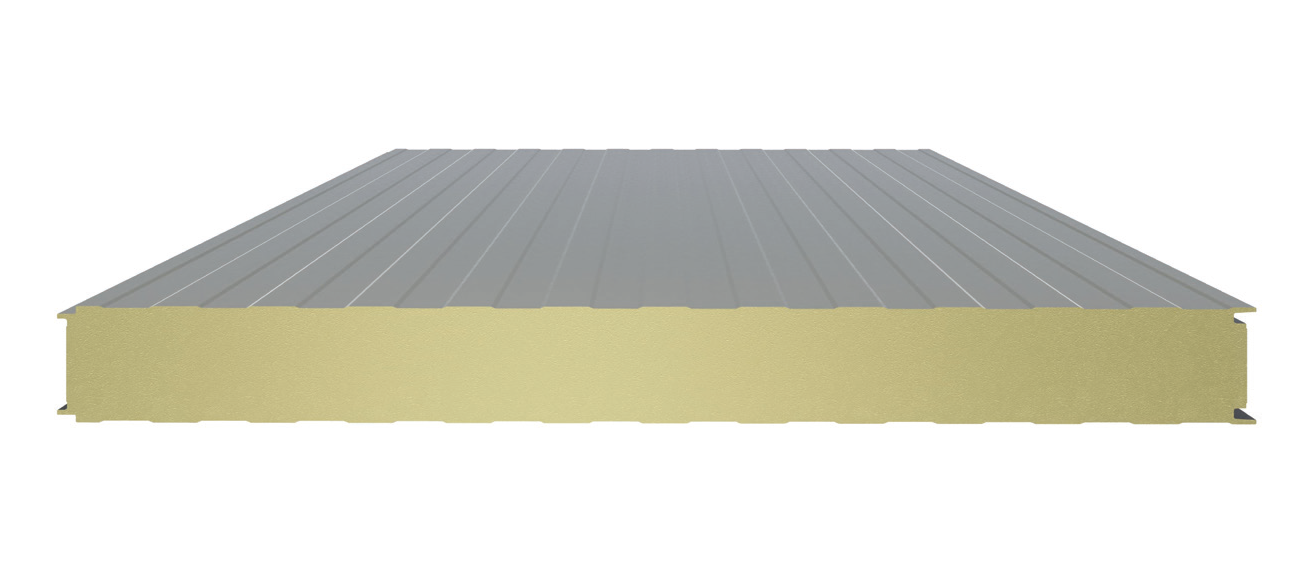

Geopanel cold room panels prevent formation of thermal bridge with the help of its special connec tion detail, ensure impermeability and thus meet high thermal control needs. Preferred at structures that necessitate high level of thermal insulation such as food processing, frozen food, medicine, frozen depots and clean rooms, as well as at hygienically highsafety requiring environment, our panels can be manufactured at different thicknesses at width of 1000 mm depend ing on the demands, and withPolyurethane (PUR) - Polyisocyanurate (PIR) insulation options. In order to improve the impermeability at the connection detail of two panels, 3-5 mm gap has been left for mastic/ sealant application. Thereby, energy efficiency has been elevated to thehighest level

Technical Specifications

| Core Thicknesses (K) | Insulation Density | Steel Thickness PPGI | Thermal Conductivity | Reaction To Fire |

|---|---|---|---|---|

| 75, 100, 150, 200 mm | PUR 40 (±2) kg/m3 PIR 42 (±3) kg/m3 |

External Thickness

0,50-0,60-0,70-0,

80 mm Internal Thickness 0,40-0,50-0,60-0, 70-0,80 mm |

λ = 0,022 W/mK | PUR Bs2d0 EN 13501-1 Bs3d0 EN 13501-1 Cs2d0 EN 13501-1 Cs3d0 EN 13501-1 PIR Bs1d0 EN 13501-1, FM Bs2d0 EN 13501-1 |

Load Tables & “U-R” Values

| Material Thickness | Insulation Thickness | Span | Span Distance (mm) p=kg/m2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1000 | 1500 | 2000 | 2500 | 3000 | U Value | R Value | |||

| 0,50 / 0,40 | 40 | 2 | 298 | 190 | 140 | 111 | 92 | 0,55 | 1,82 |

| 3 | 343 | 218 | 160 | 127 | 106 | ||||

| 50 | 2 | 382 | 242 | 177 | 140 | 116 | 0,44 | 2,27 | |

| 3 | 439 | 279 | 204 | 161 | 133 | ||||

| 60 | 2 | 466 | 296 | 216 | 170 | 140 | 0,37 | 2,73 | |

| 3 | 536 | 340 | 248 | 195 | 161 | ||||

| 80 | 2 | 638 | 405 | 294 | 231 | 190 | 0,27 | 3,64 | |

| 3 | 734 | 466 | 338 | 265 | 218 | ||||

| 100 | 2 | 812 | 517 | 375 | 293 | 241 | 0,22 | 4,54 | |

| 3 | 934 | 594 | 431 | 327 | 277 | ||||

| 120 | 2 | 987 | 630 | 457 | 356 | 292 | 0,18 | 5,45 | |

| 3 | 1135 | 724 | 525 | 410 | 336 | ||||